Dynamic inspections reduce the inspection effort

The optimized incoming goods inspection prevents defective products from entering your production

and disrupt the rest of the production process.

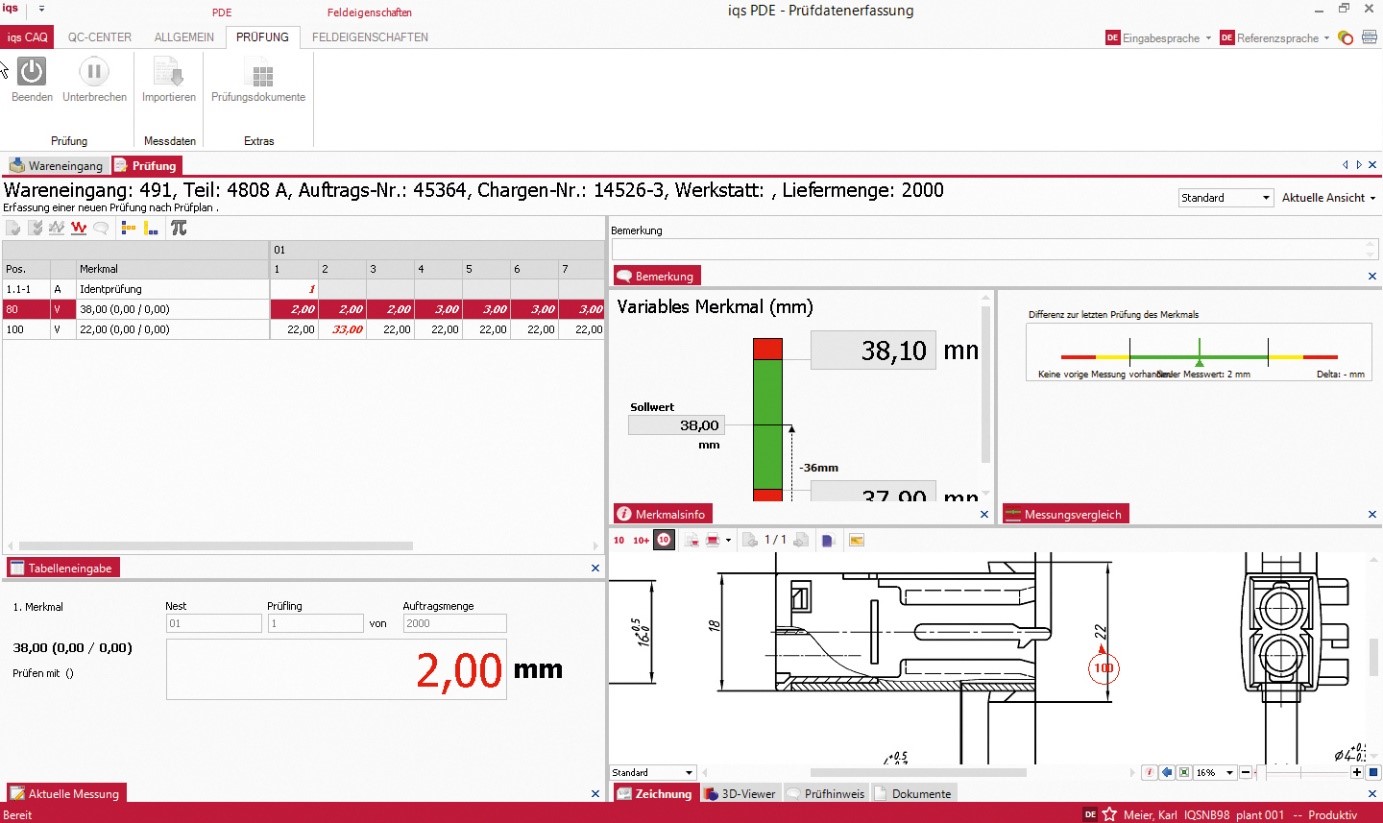

Automatic dynamic modification based on sampling plans directs the inspection effort to the right place. This saves resources in the inspection process. The inspection plans are created globally for article groups, articles or article / supplier relationships.

The process of defective products in goods receipt is further processed via a subsequent supplier complaint.

The required data from the ERP system is available in real time due to the end-to-end integration of the ERP system. This can be supplier, article, order or goods receipt information.

HIGHLIGHTS

Central test planning and CAD data integration

Inheritance technique and reuse of building blocks for product families and similar products

Versioned, inherited test plan

Sampling planning according to standards or freely definable; process and characteristic oriented, related to quantities, supplier, customer and production facilities as well as to plant and inspection location

Inspection sharpness dynamization (skiplot), also depending on complaints

Automatic generation of test orders via interfaces to ERP systems

Graphical inspection notes, e.g. by means of photos or videos